|

|

Sales & Support

Request A Quote -

Select Language

|

|

|

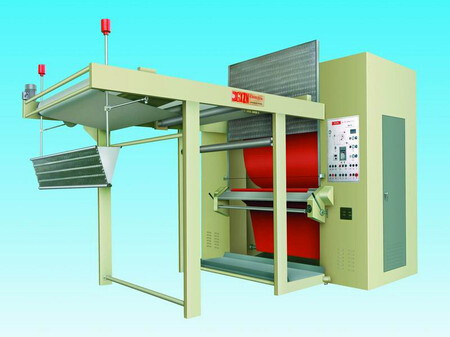

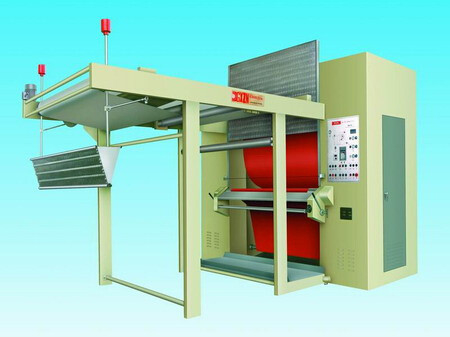

KD-YP051 high efficiency decator

|

Product Details:

Payment & Shipping Terms:

|

| Working Width: | 1800mm | Operating Speed: | 1-50m/min |

|---|---|---|---|

| Cropping Way: | Plate Or Saddle | ||

| Highlight: | textile finishing machinery,textile finishing equipment |

||

KD-YP051 high efficiency decator /decatizer /blowing machine New technology Good quality

Main technical parameters:

- Max fabric working width: 1800mm

- Fabric operating speed: 1-50m/min

- Max decating length for each time: 500m

- Cropping way: plate or saddle (optional)

- Controlling way: manual or automatic

- Vapor max consumption: 40kg/km

- Motor power consumption: 40kw

- Steaming pipe: DN40, steaming pressure: 2.5~3bar

- Compressed air pressure: ≥6bar

- Compensation power for outside steam: 15kw

- Overall dimensions: 7100×4880×2950mm

- Machine weight: about 5 T

Introduction

Today wool fabric after-finishing include two parts: wet-finishing (including dyeing) and dry-finishing. The main production device: heat setting machine, brushing machine, shearing machine, conditioning machine, pressing machine, pre-shrinking machine and decator, the decator is one of the key device and is also the ending processed device.

Decating device includes normal temperature and pressure (mainly used for processing pure wool products) and high temperature and pressure (full decatizing). It is suitable for Wool-polyester blended products processing

In today domestic normal temperature and pressure decating device, N711 is the first generation product, MB441 is the second generation product, YP-051 is the third product.

Features of this decator:

- Lapping cloth is dry and not easy to wet.

- Lapping cloth will not off tracking. (Machine equipped with a photoelectric auto-centering device)

- Cloth feeding and outlet is easy to operate. (Simply to control a lever, you can complete the forward, backward, stop, speed up, and slow down operation)

- Lapping cloth tension can regulate according to the process requirement. (0~6bar)

- Winding adopt inverter closed-loop speed control, debatching adopt closed-loop process control (Truly realize a constant linear speed, constant tension control)

- Decating include manual and automatic (optional): Manual operation or Automatic variable control system

- Automatically adjusts the steam roller before steam open the steam program, stop in a fixed bit of steam when the steam roller, (not running) and the steam does lining do not need to disengage and roll under it.

- A conveyer belt, can achieve a draining cold (exodus can also choose not to smoke when cold) cropping method has two optional (saddle placement or flat place).

- Replace decating crinoline on the conveyor belt directly out of cloth, avoid labor

- Machine put in place a special steam outside compensation device (option), its biggest advantage is that make steam no inner and outer layer of the fabric after differences, to achieve uniform temperature inside and outside. By the measurement of paper detected N711 MB441 steamed in the steaming process around inner and outer temperature difference in 10~15℃, whereas new decating machines without compensating device around inner and outer temperature difference at 5 ° c, when inner and outer temperature of the same under an increased compensation. This system can effectively control does not match the color generated by the steam and horse difference.

- Large-diameter steam rollers (steam roller diameter 900mm), large cloth holding capacity and high yieldSteamed rolls, wrap cloth roll storage, fabric rolls are used in AC frequency conversion motor, frequency control, smooth transmission, synchronous speed precisely, on the precise speed and tension control.

- PLC, touch screen and frequency changing consists of an advanced control system, touch-screen design rich interfaces, operate the touch screen it is easy for a variety of process parameters and procedures for selection, set, adjustments and changes, so as to obtain the best effect of decating. Also can be easily observed at random via a touch screen operation. Set up a sound safety protection devices and systems, and has a fault self-diagnosis and alarm system, can be easily diagnosed via a touch screen fault, fault location and handling methods. PLC and program automatic control of all process parameters.

![]()

Contact Person: Mr. Toby

Tel: +8618921102679

-

Tubular Knitted fabric singeing machine

-

KD-YP051 high efficiency decator

-

long loop steaming machine

-

Knitted open-width singeing machine / Textile Finishing Machines after slitted

-

Double roller natural luster fabric rolling machine for polishing of fabrics

-

Overfeed expanding Textile Finishing Machines for expanding and calendaring